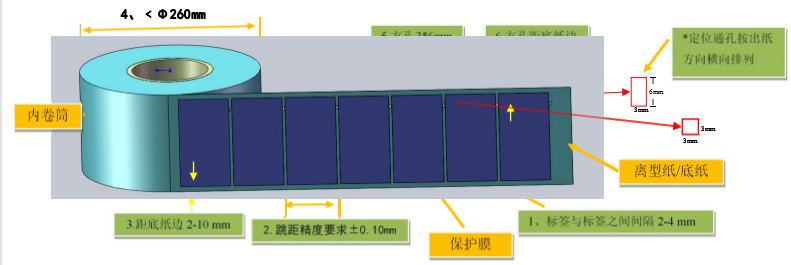

1.離(li)型紙/底(di)紙 :用 PET 底(di)紙(材(cai)質透明)或者格拉(la)辛(xin)底(di)紙,兩種材(cai)質的離(li)型紙具(ju)有良好的韌性,可(ke)適應貼膜機(ji)的高(gao)速 運轉;

2.模切保(bao)護(hu)膜時,模切精度要求±0.01mm,避免切傷底紙,否(fou)則會引起斷標;

3.標(biao)簽(qian)與(yu)標(biao)簽(qian)之(zhi)間間隔 2~4mm,跳距(ju)精(jing)度要求±0.10mm,否則會(hui)引起貼標(biao)簽(qian)前后位置(zhi)不準; 4.標(biao)簽(qian)距(ju)離底紙邊沿 2~10mm;

5.標簽卷芯(xin)內徑(jing)Φ76±1mm,外徑(jing)小于(yu)Φ260mm ,且卷芯(xin)寬(kuan)度與底紙寬(kuan)度一樣(yang);

6.如透(tou)明標簽(qian),底(di)紙(zhi)為(wei)不透(tou)明,可以在底(di)紙(zhi)邊緣打方孔(kong)檢測,尺(chi)寸為(wei) 6*3mm(建議(yi)盡量選擇 6*3mm)或(huo) 3*3mm;。

7.如透明(ming)(ming)標簽(qian),底紙(zhi)為透明(ming)(ming),同樣可(ke)以在底紙(zhi)邊緣打(da)方孔檢(jian)(jian)測,尺寸為 6*3mm(建議(yi)盡量選擇 6*3mm)或 3*3mm;或更(geng)換透明(ming)(ming)標簽(qian)電眼(yan)(建議(yi)盡量打(da)方孔,檢(jian)(jian)測效(xiao)果(guo)更(geng)好精度更(geng)高)。定位方孔距底紙(zhi)邊 5-30mm.

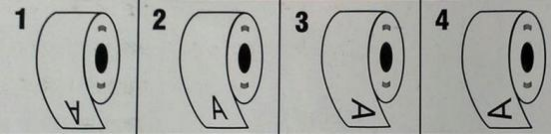

8.出(chu)標方向有左出(chu)右出(chu)和前(qian)出(chu)后出(chu)四種(zhong)(zhong),具體哪(na)種(zhong)(zhong)跟所配套的機型有關,需確認,如(ru)下(xia)圖所示:

高新技術企業

高新技術企業 全國免費熱線:

400-888-4146

全國免費熱線:

400-888-4146 座機:0769-22867596

座機:0769-22867596 ds@dgdeshang.com.cn

ds@dgdeshang.com.cn